|

Hangar Construction Project

- Archives 2009

For more recent photos

go here.

Added

1/8/10 , updated 7/26/13. Click on any photo for a larger view.

December 29, 2009.

Finally, all of the sheathing is done. I used 1/2" CDX ply on the corners

and OSB in between.

November 17, 2009.

Here, I'm installing sheathing using my old Bostitch pneumatic framing nail gun. Notice the

frame outs for the windows and doors.

November 11, 2009. I

hired an electrician to bring 200 amp service into the hangar from the house.

He also buried a conduit between the house and hangar for telcom/data lines and a

second conduit for future high voltage lines so I could control lights or other

devices in the hangar from the house. I will finish the electrical work

myself.

Local codes here allow homeowners to apply for a permit and do work on their own

place.

October 30, 2009. A

view of the hangar door opening from the inside. The clear opening is 42'

x 12'. Temporary diagonal braces are in place to help keep things square

until the framing and sheathing are complete.

October 26, 2009. After

the concrete pour, my first project was to frame in the corners so they can be

sheathed with CDX plywood. Ply in the corners provides strength to avoid

racking. 2x6 studs are installed between the 6x6 posts on 24" centers. The

studs and posts are then faired out with 2x lumber to match the footprint of the band board and header.

Framing it this way will allow the future installation of insulation and

drywall, if I decide to someday finish the interior.

October 13, 2009.

With the main slab complete, work moves to the 20' x 32' apron.

October 12, 2009. I

hired a local concrete finisher to pour the 5" slab. The band board serves

as a former. Care is taken not to damage the tubing.

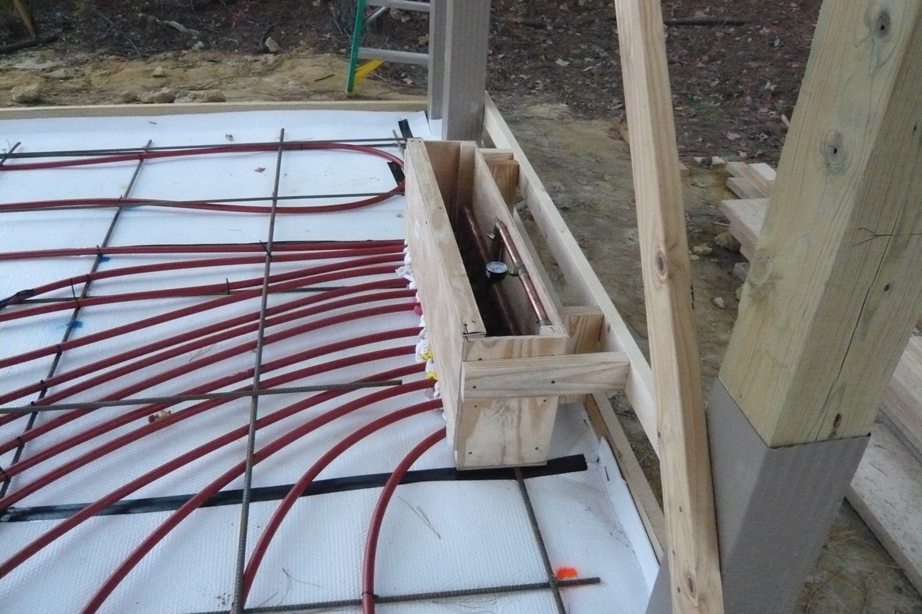

October 7, 2009. I laid out the tubing for the radiant

heating prior to the slab pour. After the base is prepared, a layer of

double-bubble reflective insulation is laid down. The insulation rolls up

the side of the band board. Once the insulation was down, the concrete

contractor laid down one layer of rebar in a grid pattern, 48" on center.

Once the rebar was down, I laid out the tubing in 6 equal length loops, each

connected to the input and output sides of the manifold. After all

connections were complete, I pressure tested the system. Following the

tubing installation, a second layer of rebar was laid down in an offset grid

pattern, 48" on center, so that the final rebar grid is at 24" on center.

Thus the tubing is sandwiched between two layers of rebar, helping to keep it in

position. The tubing is attached to the rebar with zip ties. The box around the manifold serves as a former for the concrete pour. Rags

are stuffed around the tubes where they enter the box to prevent the concrete

from flowing into the manifold box. After the cement set, the box was

cut out. I ordered the materials for the radiant heat from

Radiantec.

October 2, 2009.

Here, the contractor is laying the Fabral metal roofing over the reflective

insulation. A one foot overhang and soffit all the way around provides some protection

for the walls and improves looks.

October 1, 2009.

Purlins made of 2x4's provide support for the roof insulation and roof metal.

September 30, 2009.

A super-sized fork lift is the right tool for putting the trusses in place.

The span is 50'. Trusses are set on 4 foot centers. A double truss

is placed over the large door opening. After several designs, some that

included an attached shop, I finalized on a simpler design to reduce costs.

The south facing main door faces away from the prevailing northwest winds.

September 22, 2009.

A serious post hole digger is required. There are 22 6"x6" pressure

treated posts. Each post sits on concrete and is protected with a plastic

sleeve called, somewhat predictably, a "Post

Protector."

September 7, 2009.

The trusses are delivered first, then the other materials. I contracted

with National Barn Company to put up

the posts, trusses, and roof. The hangar will be 50'x50'x14'. Roof

pitch will be 4/12.

August 17, 2009. The

project begins with some fill dirt. The hangar is sited in a low area, so many

tons of fill will raise the floor to keep things dry. A local contractor

provided the fill dirt and skid steer work, and leveled the site using a

transit. Previously, I cut and removed about 15 trees to allow for the

necessary 125 foot setback of the hangar from the runway. As with the

house project, the goal was to remove no more trees than necessary.

Back

to the Hangar 9 Aeroworks Main Page

|